Typically, C-frame presses are designed to take up less floor space than other presses as well as to provide minimal stroke deflection. Additional benefits of C-frame presses include work accessibility, increased open area, and work approach advantages. Read More…

The hydraulic press industry is competitive, but in a sea of competitors, we are among the best! We offer ISO 9000:2000 certification, and we work with customers to create the ideal designs for their unique circumstances.

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

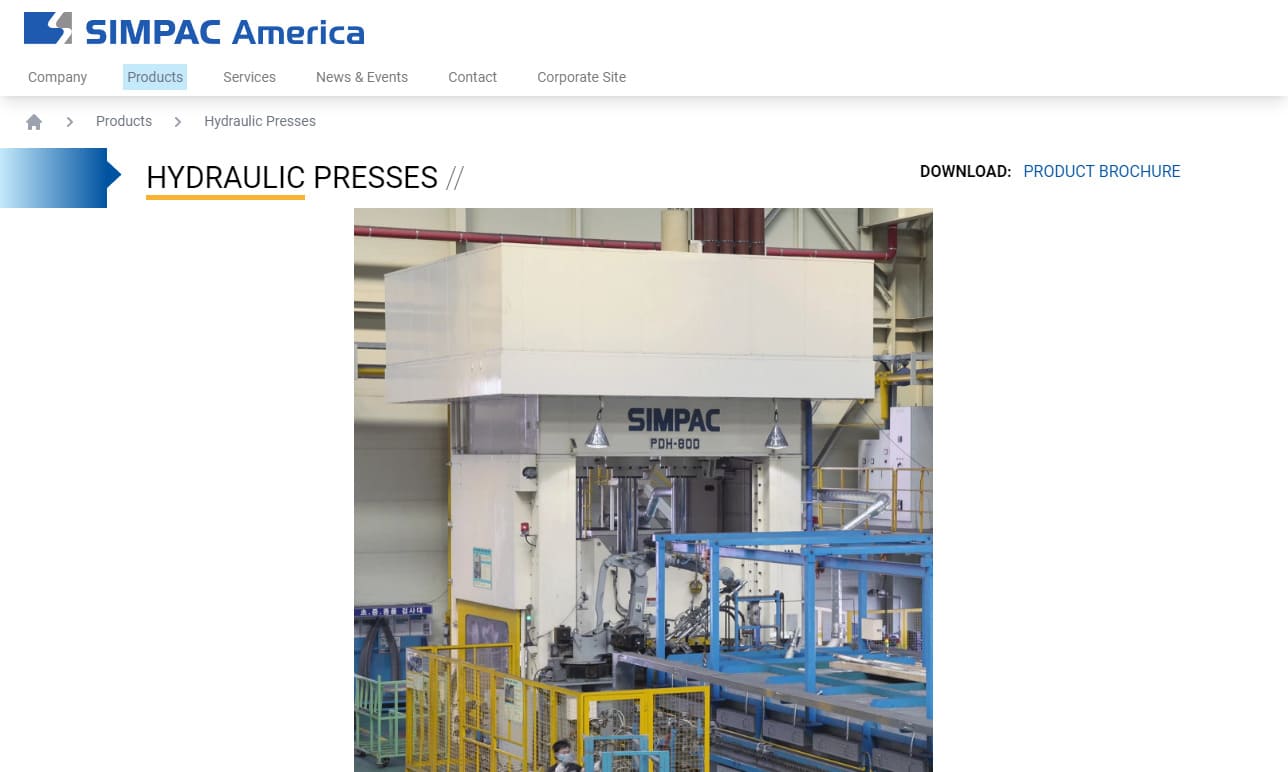

At SIMPAC America Co. Ltd., we are at the forefront of precision engineering and innovative solutions in the field of mechanical presses, servo presses, and hydraulic presses. With a commitment to excellence and a rich legacy spanning several decades, we have established ourselves as a trusted name in the manufacturing industry. SIMPAC America offers a comprehensive range of mechanical presses...

Air-Hydraulics is a manufacturer of air presses and a variety of hydraulic presses, including pneumatic air presses, power presses, hydraulic press stamping and assembly presses. We are ISO 9001:2000 certified and have been designing press machinery for metal forming and stamping since 1945.

More C-Frame Press Manufacturers

Offering precision and control, C-Frame presses are used in a diverse collection of applications including punching, blanking, coining, straightening, forming, bending, drawing and assembly work.

As a result of the wide range of applications that C-frame presses can be utilized for, there is a broad spectrum of industries that depend upon their various services including:

industrial, in the manufacturing and fabrication of a variety of hardware including fasteners and spring clips; automotive, in order to form parts such as engine mounts, connectors and terminal lead frames; medical, to form critical devices including many surgical instruments; and electronics, to manufacture electrical components such as bandolier pins, electronic connectors and diverse computer parts.

Stamped parts from C-frame presses are formed from a range of sheet metal materials including copper, titanium, stainless steel, and aluminum.

There are many different designs that fall under the heading of a C-frame press. However, at its most basic, a C-frame press consists of a ram, or press, a die and a press bed.

Stampings are formed by means of the die, a press tool consisting of a specially designed cavity, which is used to shapes metal parts from the inserted sheet metal. The upper component of the die is connected to the press slide, and the lower component id connected to the press bed.

The ram then performs the necessary shaping operation by pushing the sheet metal through the die. An example of a special type of C-frame press is one that features a crown suspended over the press bed and an open portion in the front of the press that allows for easy access to the die set. C-frame presses are able to be operated manually or automatically, and are typically a type of mechanical press versus a type of hydraulic press.

In addition, C-frame presses are able to take up less floor space than most hydraulic presses due to their narrow and yet sturdy C-shaped frame. The frame of the press is typically made from steel because of its favorable characteristics for stamping applications, including the ability to provide minimal deflection.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services