Transfer presses combine the best features of compression molding with all the advantages of injection molding. A transfer press, like a plastic injection molding machine, has the capability to produce plastics with high productivity. In addition, a transfer press is an automated multi-stage press characterized by a high degree of automation. Read More…

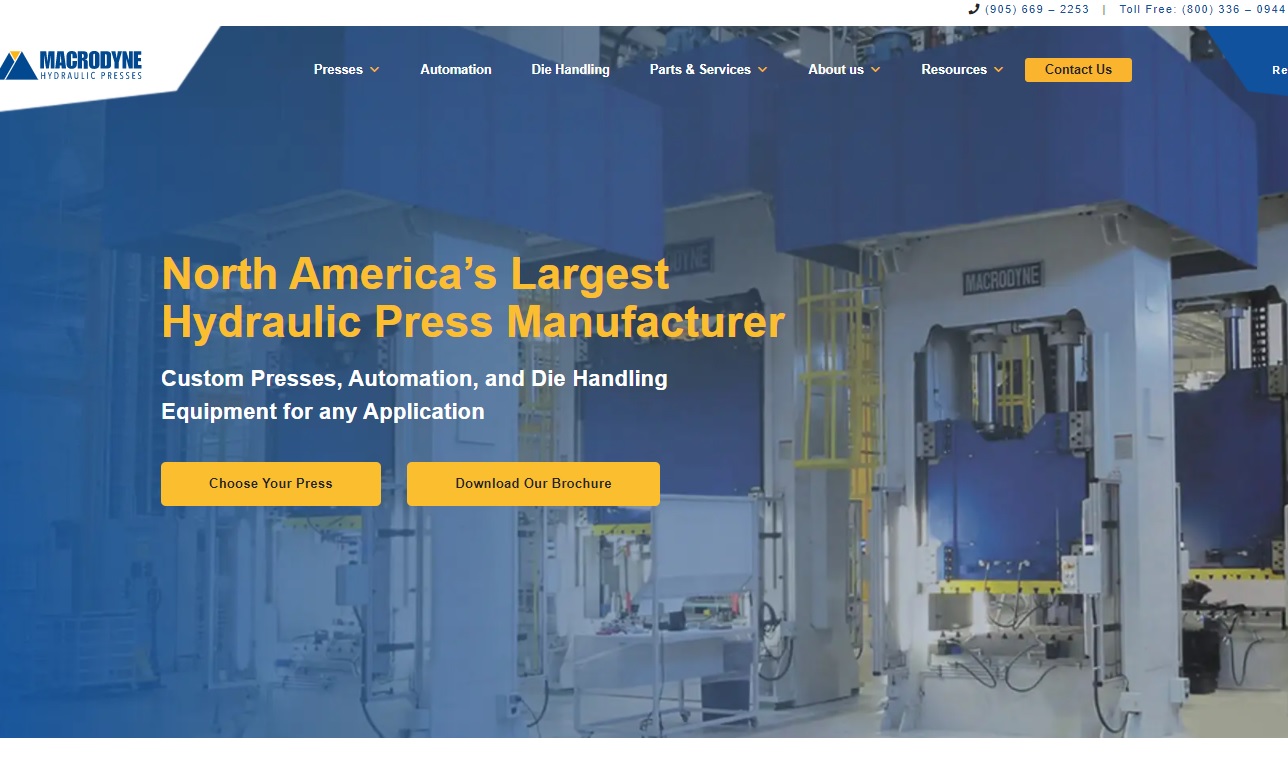

The hydraulic press industry is competitive, but in a sea of competitors, we are among the best! We offer ISO 9000:2000 certification, and we work with customers to create the ideal designs for their unique circumstances.

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

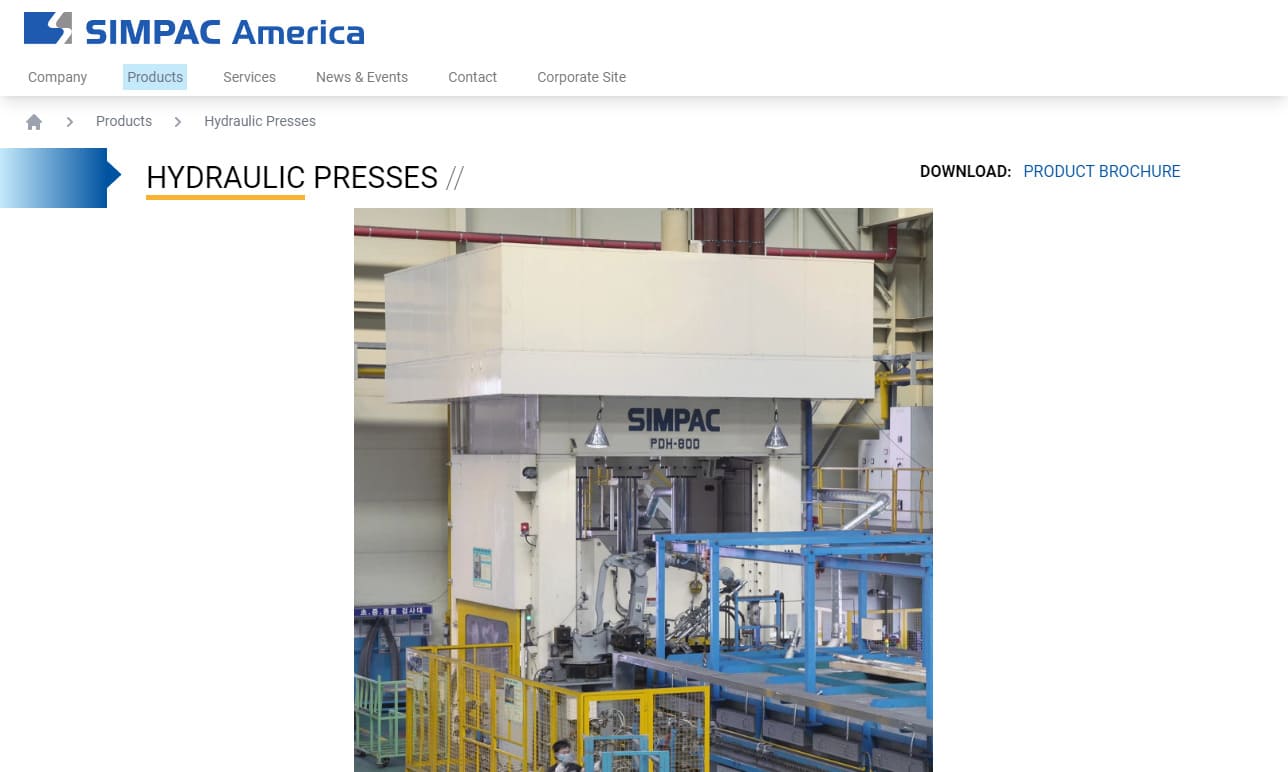

At SIMPAC America Co. Ltd., we are at the forefront of precision engineering and innovative solutions in the field of mechanical presses, servo presses, and hydraulic presses. With a commitment to excellence and a rich legacy spanning several decades, we have established ourselves as a trusted name in the manufacturing industry. SIMPAC America offers a comprehensive range of mechanical presses...

Air-Hydraulics is a manufacturer of air presses and a variety of hydraulic presses, including pneumatic air presses, power presses, hydraulic press stamping and assembly presses. We are ISO 9001:2000 certified and have been designing press machinery for metal forming and stamping since 1945.

More Transfer Press Manufacturers

A transfer press is often utilized in textile finishing, where flex films, flock foils, screen printing transfers, toner transfers, or other media are pressed onto textiles. There are many different transfer presses, but the most commonly used are vibrating and folding presses. Transfer presses are excellent options for the production of stampings, and they offer the benefits of lower tooling costs. In a transfer press, feeding is done through a coil processing line, a parts loader, or a blank loader. When the forming process is complete, the finished parts are discharged from the transfer press employing a finished parts conveyor.

How a Transfer Press Works

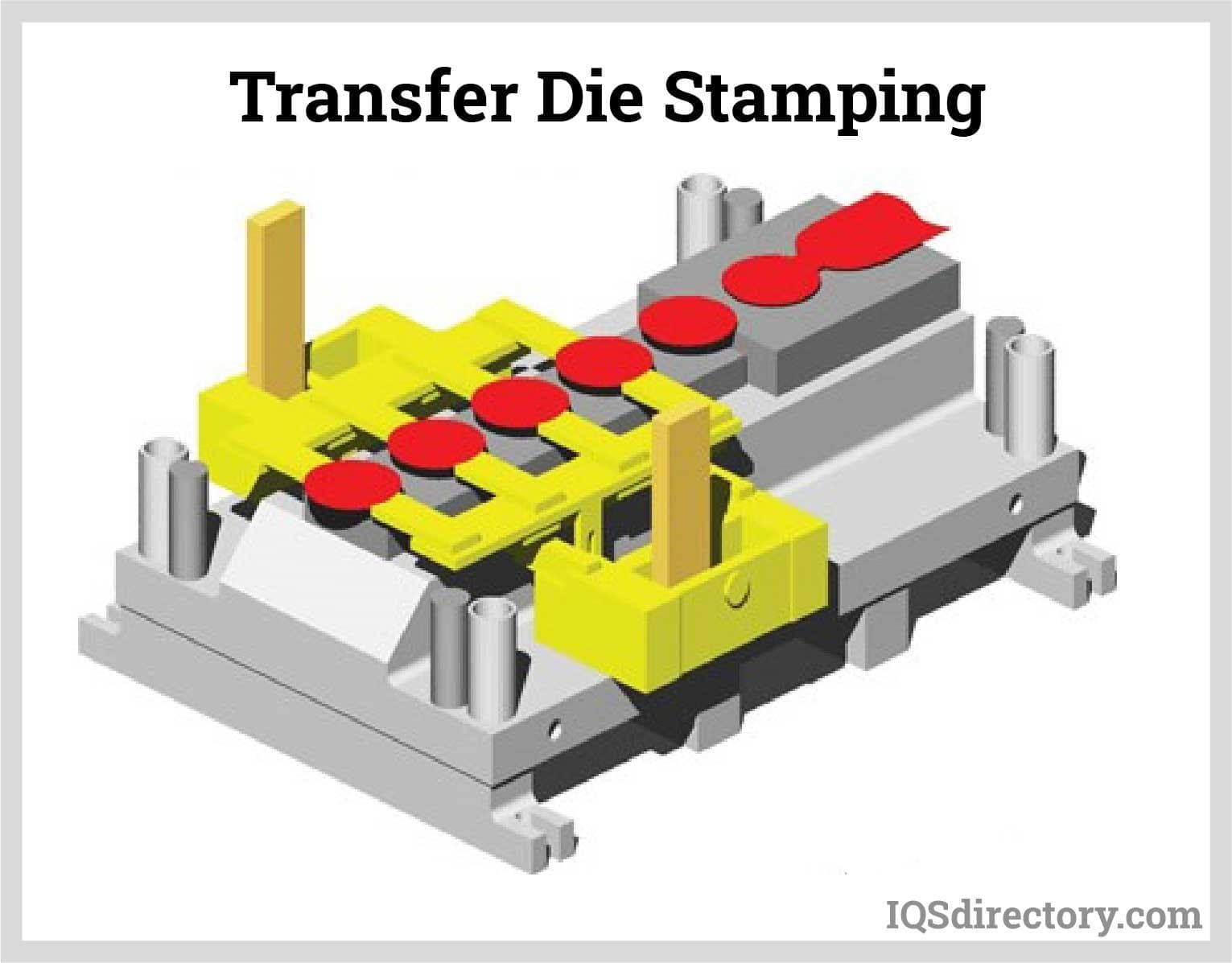

A transfer press works by transferring the workpiece from one station to another through a hydraulic transport system. They are mostly utilized in cases where the workpiece has to be free from the strip to perform operations freely. The transfer press process is similar to the progressive die stamping process, but the main difference between these processes is that the transfer press process separates the workpiece from the main strip found in the first step. Then, it transfers it from one station to another using a hydraulic transport system.

On the other hand, in progressive die stamping, the main strip is automatically progressed from one station to the other and then separated from the main strip in the final step. A transfer press can be a single press by itself or many machines arranged in a row to form a production line. The transfer press process is initialized with a metal strip fed into the first station. This is where the blank is cut from the strip for the component. The blank is then transferred hydraulically by transferring fingers carrying the part through different forming stations to completion. The transfer of all parts to the next station occurs simultaneously. These presses consist of a large opening in the uprights. This opening enables flexible stamping of the parts utilizing transfer dies. Transfer presses use efficient hydraulics like Schuler’s ring valve to achieve high output. They can also use hydraulic cylinders by switching them among multi-modes.

Types of Transfer Presses

The types of transfer presses include:

Individual Cam Operated Plungers

A single cam-operated plunger can act like multiple presses in one. The movement of each station is independent of the others, and the integrated mechanism of transfer synchronizes their operations. This type of transfer press enables easy customization through each production run.

Solid Bed Die Set Press

This type of transfer press is like an individual cam-operated plunger but features independent synchronized press stations. A solid bed press does not use a rotary mechanism. Instead, it uses a flat surface that starts the press motion and simultaneously activates multiple stations.

Applications and Uses of Transfer Presses

Transfer presses are utilized in:

- Frames and structural components.

- Large parts requiring transfer among many presses for completion.

- Shell and tube applications.

Benefits of Transfer Presses

- They are extremely versatile machines, and multiple parts like chamfering, pierced holes, ribs, cut-outs, threading, and knurls can be designed into primary press operations. This eliminates the need for additional costs involved in multiple secondary operations.

- Transfer presses bring broader setup flexibility. They can employ a series of dies, a single die, or a series of machines arranged in a row to accommodate different project requirements.

- Transfer presses are associated with simpler stamping operations.

- Transfer presses are better suited for mass production. The transfer press process requires accurate and precise alignment and smooth transfer between steps.

- They are reliable.

- They are associated with automatic and fast die change.

- They are associated with programmable motion capabilities.

Choosing the Proper Transfer Press Manufacturer

To ensure you have the most positive outcome when purchasing a transfer press from a transfer press manufacturer, it is important to compare several companies using our directory of transfer press manufacturers. Each transfer press manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each transfer press business website using our patented website previewer to quickly learn what each business specializes in. Then, use our simple RFQ form to contact multiple transfer press companies with the same form.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services