Mainly used to manufacture composite materials, one of the most common applications for platen presses is in the forestry industry to condense wood material and forest products, producing composites like particle board and plywood. Read More…

The hydraulic press industry is competitive, but in a sea of competitors, we are among the best! We offer ISO 9000:2000 certification, and we work with customers to create the ideal designs for their unique circumstances.

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

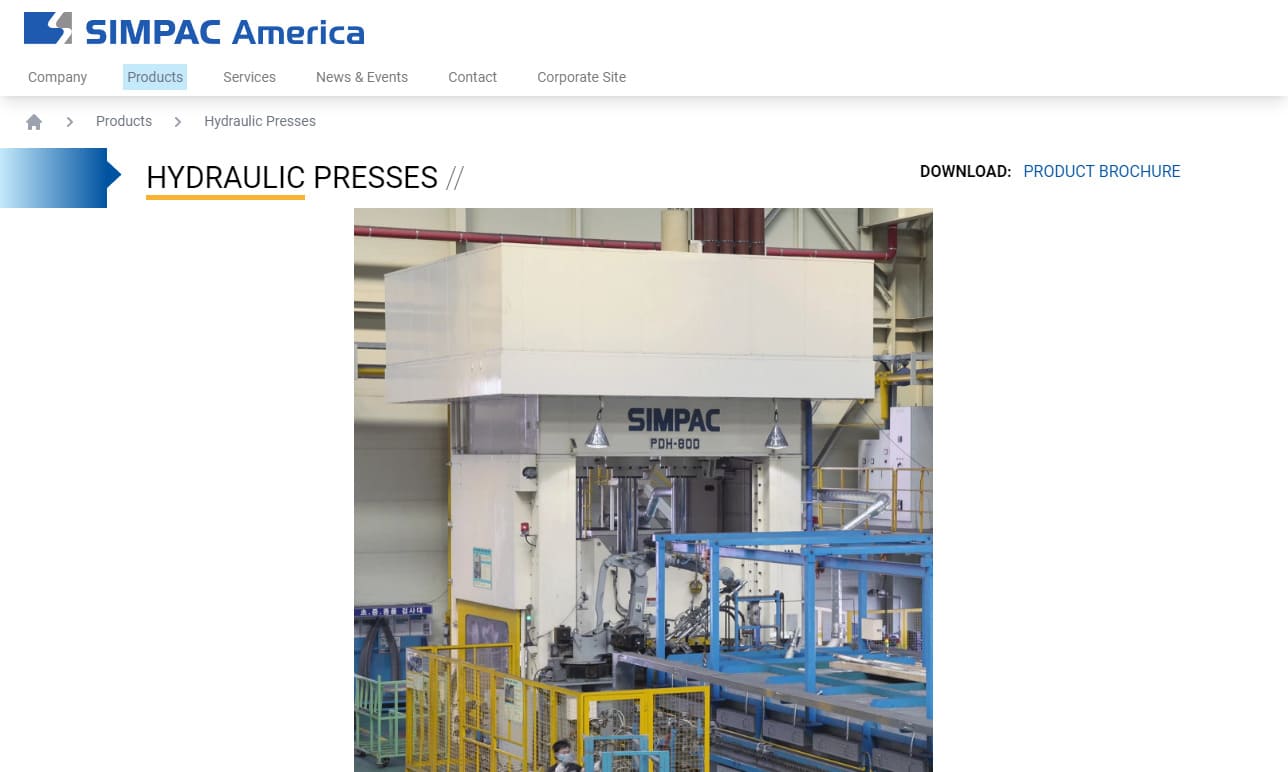

At SIMPAC America Co. Ltd., we are at the forefront of precision engineering and innovative solutions in the field of mechanical presses, servo presses, and hydraulic presses. With a commitment to excellence and a rich legacy spanning several decades, we have established ourselves as a trusted name in the manufacturing industry. SIMPAC America offers a comprehensive range of mechanical presses...

Air-Hydraulics is a manufacturer of air presses and a variety of hydraulic presses, including pneumatic air presses, power presses, hydraulic press stamping and assembly presses. We are ISO 9001:2000 certified and have been designing press machinery for metal forming and stamping since 1945.

More Platen Press Manufacturers

Platen presses form a vast variety of products, including rubber and plastic products such as mats and sheets. Additionally, the aircraft and aerospace industries use platen presses for airplane components like noses, nacelles, doors and seating structures.

Conveyor belts, bullet-proof helmets and body armor, car bodies, ship components, some furniture, tires, stainless steel kitchen sinks, appliance parts, laminate, freeway signs, honeycomb panels and other structural components are also formed by platen presses because they are able to easily form even the toughest materials by using so much force in combination with heat.

Research and testing facilities use platen presses for impact testing by crushing the test object between two platens. In plastic packaging, the vacuum molding machines that seal the plastic around the product are considered platen presses, since the plastic edges are crushed and melted between two heated metal plates.

Platen presses are hydraulically powered and use extreme amounts of pressure to compact different materials together to form a new product or reduce the size of scraps. This type of hydraulic press is defined by the large, heavy, flat metal plates that crush and condense materials between them.

The design of these plates features a bottom and top platen, stacked upon each other and while the bottom platen usually remains stationary, the top one moves up and down.

Molded products like kitchen sinks and tires are formed by platen presses that have molds attached to the platens. Each platen weighs several tons, and is considered the heaviest and strongest component of the press.

The platens are heated by oil, steam, water or electricity, and raise the temperature enough so that the material is malleable, but not molten.

In order to produce a quality product, platen presses must have temperature uniformity throughout each platen, even load distribution, temperature range and platen stability under high pressure.

Every component in a platen press is made of structural steel; the platens are most often stainless steel. They are often equipped with rapid cooling systems to quicken the forming process by decreasing the product's cure and dry time.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services