Press brakes are machines used in the bending of sheet metals. They are narrow and long so that any size of sheet metal can be easily bent. The traditional press brake machines are vertical, but the horizontal types are able to form long or narrow pieces of sheet metal that are usually difficult to bend. The press brake can bend a sheet metal several times until the required shape is reached. Read More…

The hydraulic press industry is competitive, but in a sea of competitors, we are among the best! We offer ISO 9000:2000 certification, and we work with customers to create the ideal designs for their unique circumstances.

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

At SIMPAC America Co. Ltd., we are at the forefront of precision engineering and innovative solutions in the field of mechanical presses, servo presses, and hydraulic presses. With a commitment to excellence and a rich legacy spanning several decades, we have established ourselves as a trusted name in the manufacturing industry. SIMPAC America offers a comprehensive range of mechanical presses...

Air-Hydraulics is a manufacturer of air presses and a variety of hydraulic presses, including pneumatic air presses, power presses, hydraulic press stamping and assembly presses. We are ISO 9001:2000 certified and have been designing press machinery for metal forming and stamping since 1945.

More Press Brake Manufacturers

The press brake can bend a sheet metal by lowering a punch into sheet metal already positioned on top of a die.There are different types of press brakes, including mechanical, hydraulic, and electrical, but this article will focus on hydraulic press brakes. Hydraulic press brakes utilize pressure to force the ram down rather than mechanics.

Hydraulic press brakes can have multiple cylinders. This will give greater control to the operator over the bend. This, in turn, results in a bend that is precise and highly customizable. However, these press brakes have some disadvantages: for example, they cannot exceed their rated tonnage.

The Working Principle of Hydraulic Press Brakes

The working principle of hydraulic press brakes is based on Pascal's principle. The principle states that there is constant pressure throughout a closed system. The system consists of a piston as one part of it.

The piston acts as a pump with a small mechanical force that acts on a small cross-sectional area. The other part is a piston with a larger cross-sectional area generating a larger mechanical force. Only small-diameter tubing is needed if the pump and the press cylinder are separated.

The hydraulic press brake applies a small force on a small piston. This will create pressure which is then transferred via the hydraulic fluid. The transferred pressure will apply a greater force on the larger piston.

Types of Press Brakes

The types of press brakes include:

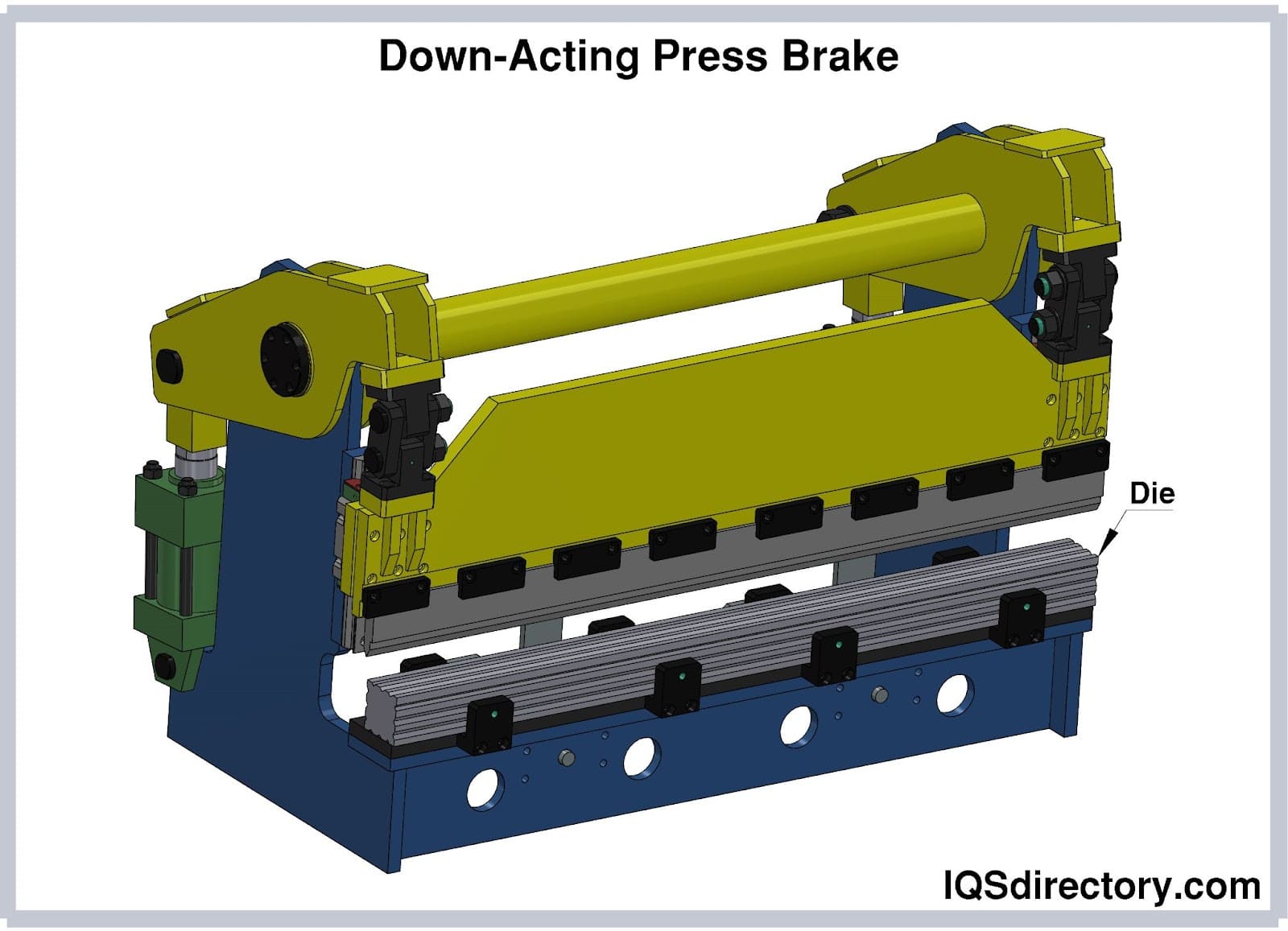

Down-Acting Press Brake

These press brakes move so that the upper arm moves downward to a fixed bed that holds the bottom die. Typically, they are driven by two or more hydraulic cylinders as well as top-mounted hydraulics. Down-acting press brakes are the most popular press brakes on the market, and most fabricators are familiar with this type of press brake.

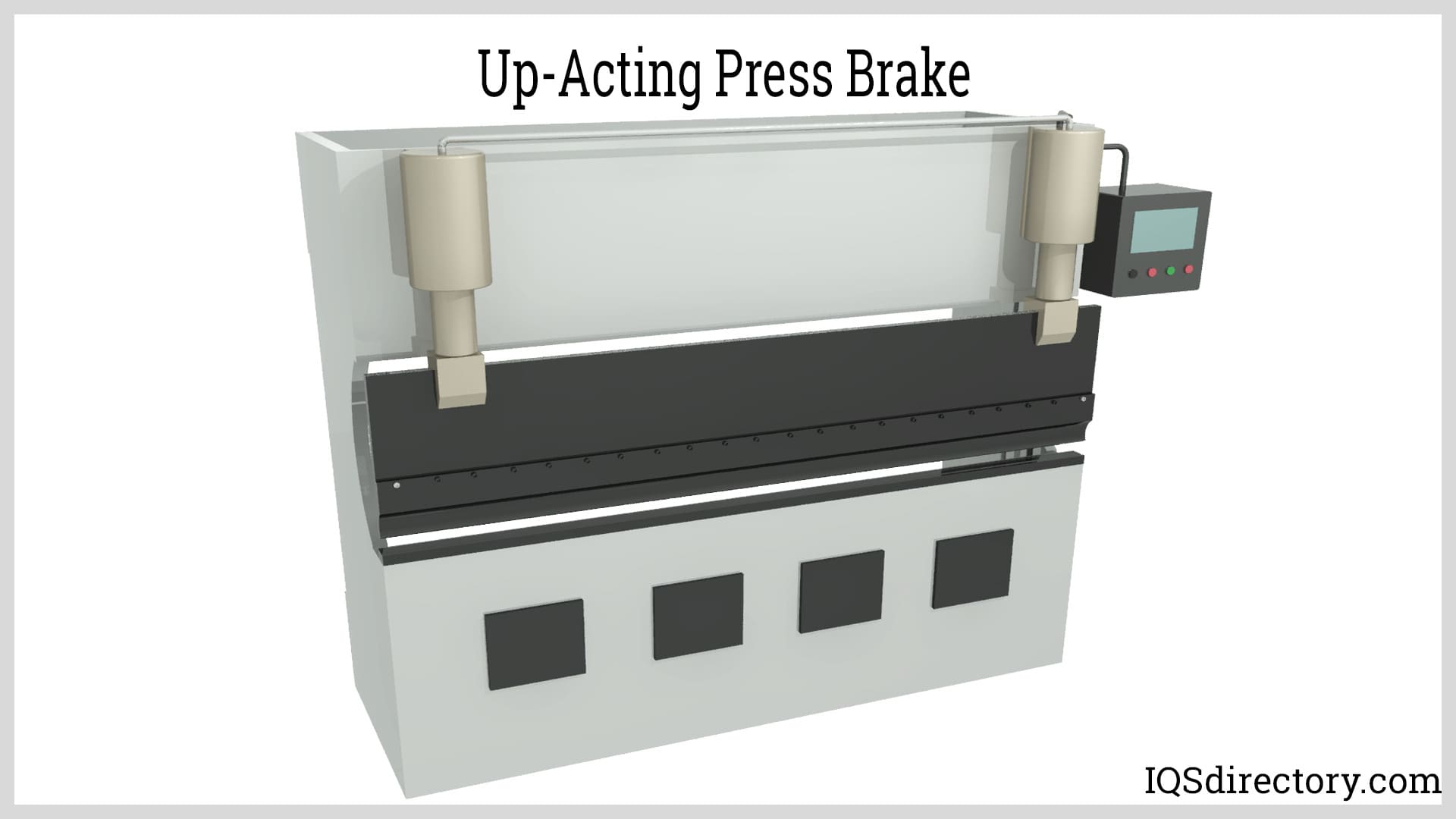

Up-Acting Press Brake

This type of press brake consists of a lower beam moving upward, carrying the die and the part towards the fixed ram, which holds the forming punch. In this method of motion, low mounting of hydraulics can be done.However, it requires the holding of the part in position by the operator, during the complete range of motion.

Applications of Press Brakes

They are used for molding, blanking, punching, metal forming, deep drawing, clinching, and forging in the following industries:

- Automotive

- Aerospace

- Marine Engineering

- Furniture

- Metal Work

- Metal Containers

- Other applications involving sheet metals

Benefits of Press Brakes

The benefits of press brakes include:

Cost Cutting

Hydraulic press brakes have a significant cost advantage compared to mechanical presses. Their replacement parts are cost-effective in case of any breakdown. The pressure of hydraulic press brakes can be set to suit the tools and the job. This reduces their tool cost and minimizes the risk of damaging the tools.

Built-in Overload Protection

Hydraulic press brakes have built-in overload protection, meaning there is a set pressure limit that the press will never exceed. The relief valve opens when it reaches its limit, so there is no need to worry about weight damage or overloading.

Quietness

The ram on the hydraulic press brake can be controlled, meaning that the machine's noise levels can also be controlled. hydraulic press consist of a lower number of moving parts and are therefore quieter than mechanical presses.

More Compact

Hydraulic press brakes can generate large amounts of pressure over smaller surface areas. Consequently, this means that these machines take up considerably less floor space.

Better Control Flexibility

Any hydraulic press job can be performed without limiting the tool life. This is due to their design making them capable of meeting multi-action operations. The ram force, the direction and speed of the force, and the release force can all be adjusted to meet the operation's needs.

Greater Versatility

Hydraulic press brakes can perform various jobs within the tonnage range, making the possibilities endless. The following are some examples that hydraulic press brakes can perform:

- Bonding

- Press fits

- Shell reductions

- Transfer molding

- Straightening

- Powered metal forming

Choosing the Right Press Brake Manufacturer

To ensure the most beneficial outcome when purchasing a press brake from a press brake manufacturer, it is important to compare several companies using our directory of press brake manufacturers. Each press brake manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each press brake business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple press brake companies with the same form.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services