Stamping presses are mainly used for the production of sheet metal. Stamping presses are metalworking machine tools used to cut or shape metal by deforming it using a die. They are capable of punching, forming, deep drawing, blanking, riveting and fine punching. In simple terms, this machine tool can be thought of as the modern-day equivalent to a hammer Read More…

The hydraulic press industry is competitive, but in a sea of competitors, we are among the best! We offer ISO 9000:2000 certification, and we work with customers to create the ideal designs for their unique circumstances.

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

At SIMPAC America Co. Ltd., we are at the forefront of precision engineering and innovative solutions in the field of mechanical presses, servo presses, and hydraulic presses. With a commitment to excellence and a rich legacy spanning several decades, we have established ourselves as a trusted name in the manufacturing industry. SIMPAC America offers a comprehensive range of mechanical presses...

Air-Hydraulics is a manufacturer of air presses and a variety of hydraulic presses, including pneumatic air presses, power presses, hydraulic press stamping and assembly presses. We are ISO 9001:2000 certified and have been designing press machinery for metal forming and stamping since 1945.

More Stamping Press Manufacturers

Components of Stamping Presses

The components of stamping presses include:

Bolster Plate

This component is mounted on top of the press bed. It is a large metal block upon which the bottom part of a die is clamped. The bolster plate is not a dynamic part; instead, it is stationary. Large presses like those utilized in the automotive industry may be equipped with die cushions integrated into the bolster plate to apply blank holder or counter draw forces. This is only necessary when a single-acting press is used for deep drawing.

The Ram/Slide

This component reciprocates and is the part where the upper die is mounted. It is a critical element that assures a long die life along with the maintenance of the die. A variety of slide guides are available, which are 8-point full length, 6-point square Gibs or 4-point V-Gibs. The bolster and slide allow the feeding of materials and dies into the presses.

The Working Principle of Stamping Presses

These machines make use of liquid pressure for the release of energy. They also use valves to decrease or increase the pressure of a liquid within the chamber. Hydraulic stamping presses are the most common machines among all presses. They are the most powerful tools and can apply 75,000 tons of power or more. The working principle of the stamping presses is based on the difference in fluid pressure. The fluid can be injected or reduced, and the piston falls or rises when the pressure changes.

Types of Stamping Presses

The types of stamping presses include:

Bench Presses

These types of stamping presses have a compact structure and are economical. They are easy to set up. They are utilized in a wide variety of jobs, from single-cycle operations to those operations that are automated cell components. Its tonnage capacity generally ranges from 3 to 50.

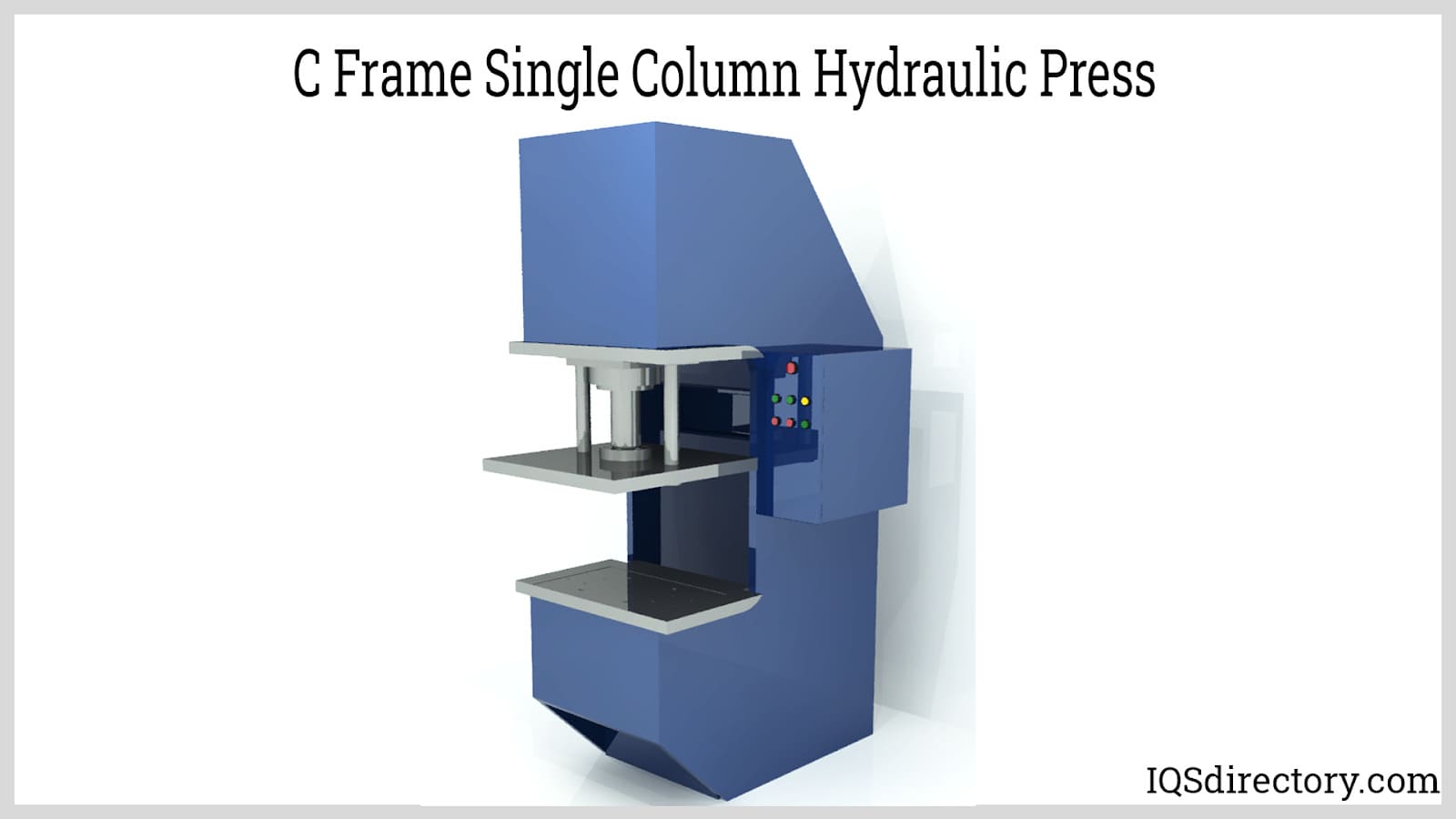

C-Frame Presses

This type of stamping press is built to provide long service in multi-shift industrial applications in 10-500 ton capacities. It was named the C-frame after its C shape.

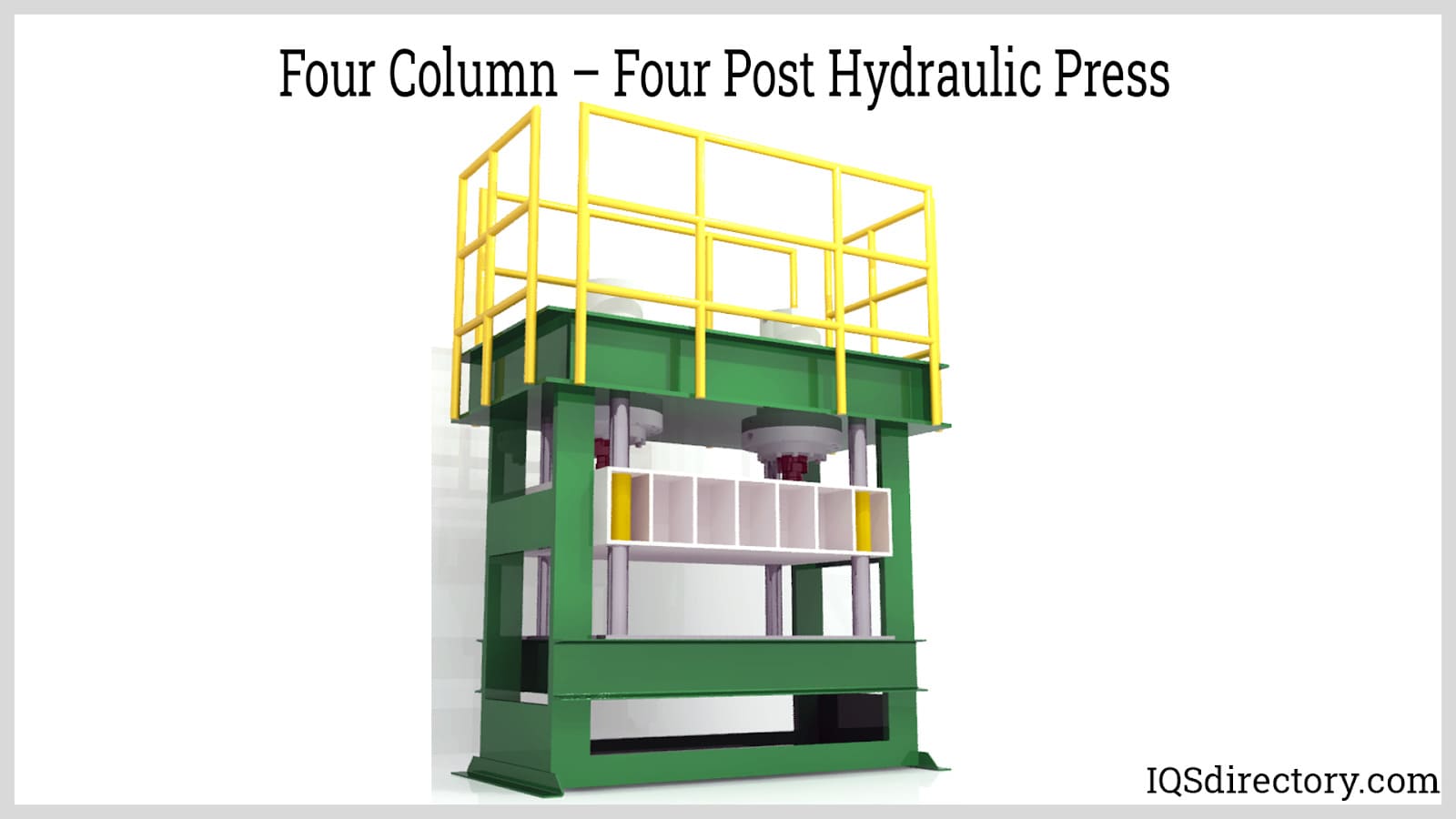

Four-Post Presses

A four-post press is a heavy-duty production stamping press built for continuous operation. It uses four heavy-duty shouldered columns of large diameter to tie the frame together. These columns serve to precision guide the moving platen presses or press slide. This will ensure exceptionally consistent lower and upper die alignment, eliminate lean-back, and minimize deflection.

Gib-Guided Presses

This type of press is designed so that it can counter the effects resulting from off-center loading. Rigid steel frames with gib-guided slides can maintain parallelism under severe loading conditions.

Applications of Stamping Presses

Stamping presses are applied in:

- Electronics

- Communication

- Computers

- Household Appliances

- Furniture

- Transportation

- Stamping of hardware parts like motorcycles, automobiles, and bicycles

Benefits of Stamping Presses

The benefits of stamping presses include:

Time Saving During Setup

Since a hydraulic stamping press can deliver its full power at any point in the stroke, there is no need to determine the exact location for maximum tonnage.

Flexible Over a Range of Applications

A hydraulic stamping press can do many jobs within its tonnage range, including high-volume production. Its common applications include deep draws, urethane bulging, piercing, straightening, staking, punching, and assembly. In addition, hydraulic stamping presses are utilized in powdered metal forming, bonding, abrasive wheel forming, broaching, ball sizing, rubber compression, and transfer molding.

Built-in Overload Protection

Since they have built-in overload protection, there are no worries about breaking the press, overloading, or smashing the die. When a hydraulic stamping press reaches its set pressure, the relief valve opens, thus eliminating any danger of overload.

Lower Operating Costs

Hydraulic stamping presses have a simple structure with few moving parts, which are completely lubricated in a pressurized oil flow. As a result, there are fewer and more minor breakdowns. The only parts likely to be replaced are solenoid coils, packing, and occasionally valves, which are inexpensive.

Minimal Cost for Larger Capacities

Compared to typical mechanical presses, a stamping press is less expensive. It is easier to buy certain capacities of hydraulic presses, with common stroke lengths of 12, 18, and 24 inches, and they can be easily equipped with extra stroke lengths. Hydraulic stamping presses can be built with larger beds and table areas. They can also be built with smaller beds than are standard.

Adjustability

With hydraulic stamping presses, the parameters such as the ram force, speed, direction, release of force, and the duration of pressure can all be adjusted to suit a particular job.

Choosing the Correct Stamping Press Supplier

To ensure you have the most beneficial outcome when purchasing a stamping press from a stamping press supplier, it is important to compare several companies using our directory of stamping press suppliers. Each stamping press supplier has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the supplier for more information or request a quote. Review each stamping press business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple stamping press companies with the same form.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services