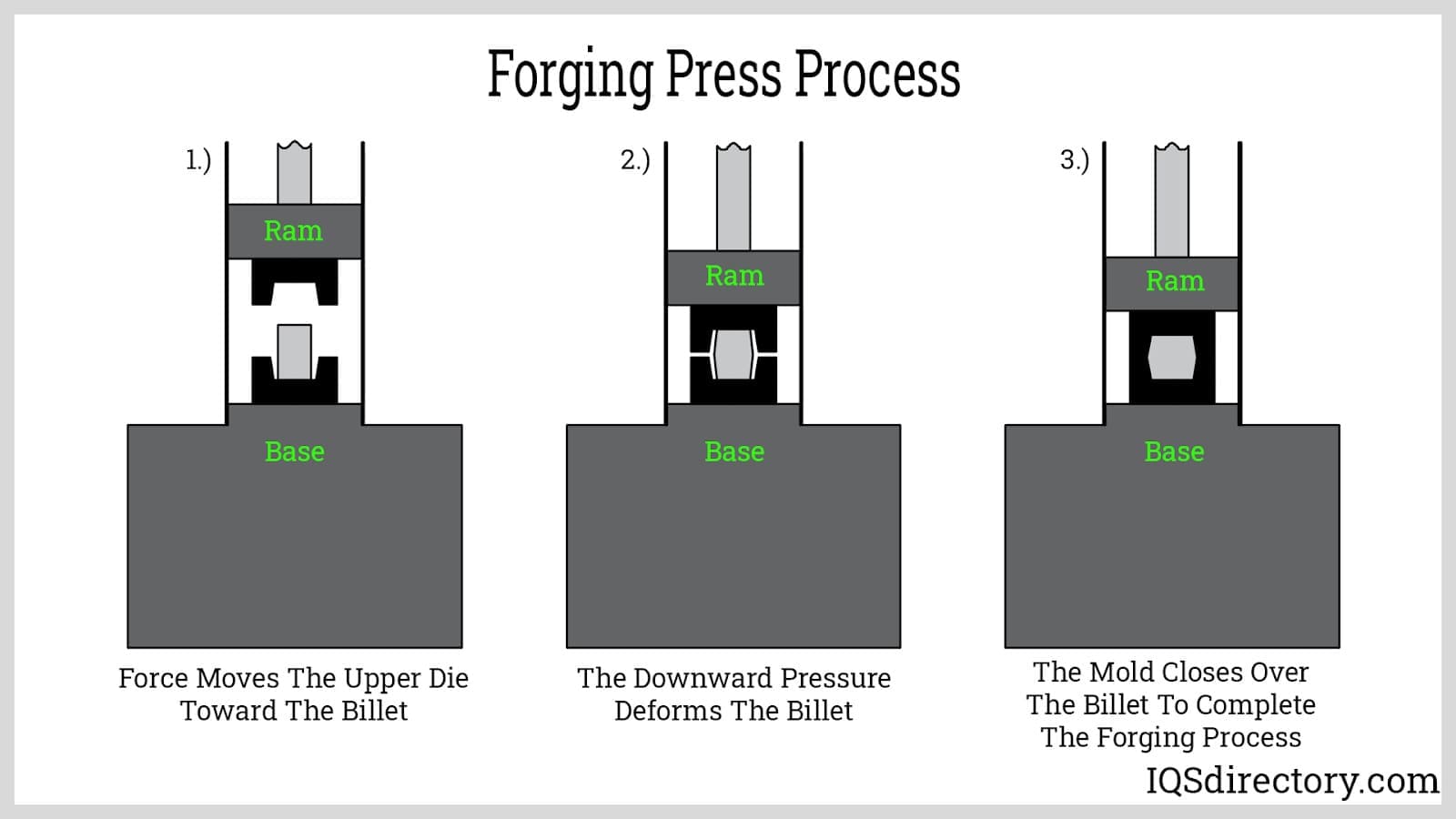

A forging press uses intense pressure between dies to push metal into shape. During the forge pressing process, metal items are shaped while being sandwiched between two dies. This uses a forging press, a device that gradually exerts pressure on a piece. The forging press technique is favored because it is less expensive than other forging techniques. In addition, the press imparts a grain flow that follows the contours of the piece, strengthening the finished product. Press forging is appropriate for high-volume forging production and can be done using either a hot or cold method. Read More…

The hydraulic press industry is competitive, but in a sea of competitors, we are among the best! We offer ISO 9000:2000 certification, and we work with customers to create the ideal designs for their unique circumstances.

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

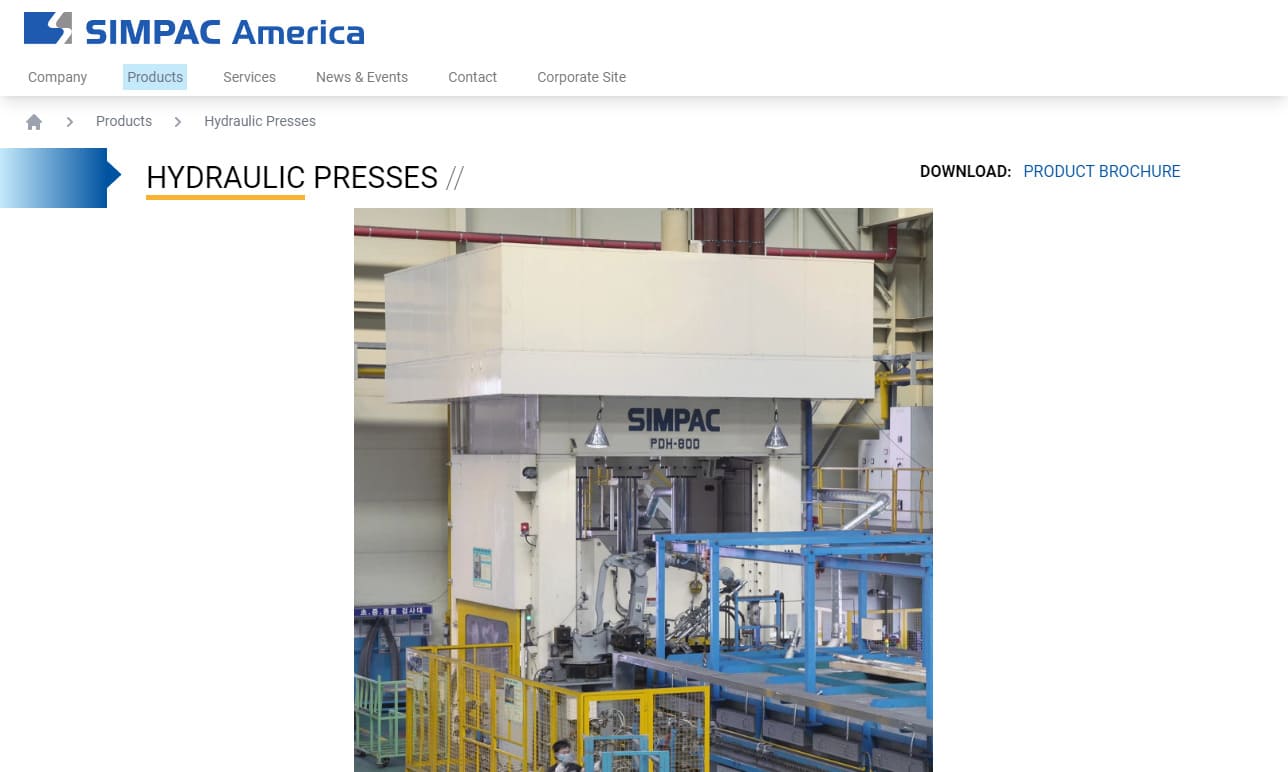

At SIMPAC America Co. Ltd., we are at the forefront of precision engineering and innovative solutions in the field of mechanical presses, servo presses, and hydraulic presses. With a commitment to excellence and a rich legacy spanning several decades, we have established ourselves as a trusted name in the manufacturing industry. SIMPAC America offers a comprehensive range of mechanical presses...

Air-Hydraulics is a manufacturer of air presses and a variety of hydraulic presses, including pneumatic air presses, power presses, hydraulic press stamping and assembly presses. We are ISO 9001:2000 certified and have been designing press machinery for metal forming and stamping since 1945.

More Forging Press Manufacturers

Types of Forging Press

Hydraulic Press

In a hydraulic press, water pressure produces the force pushing down the metal. When a hydraulic ram pounds down on a flat surface, known as an "open die," the metal is flattened and performs best. Compared to the other way, which is "closed die," this procedure is different. The dies act as molds, shaping the metal into the desired shape. They perform well in isothermal applications and are rarely used for hot forging. Large hydraulic presses have a 75,000-ton force capacity. The size and amount of force used for plastic deformation of the workpiece determine the different types of forging presses.

Pneumatic Forging Press

Compressed air, or gas is driven into a cylinder attached to the ram of a pneumatic press, providing the press with its force. When the cylinder is full, the pressure pushes the ram downward; when an escape valve releases the air or gas, the ram releases.

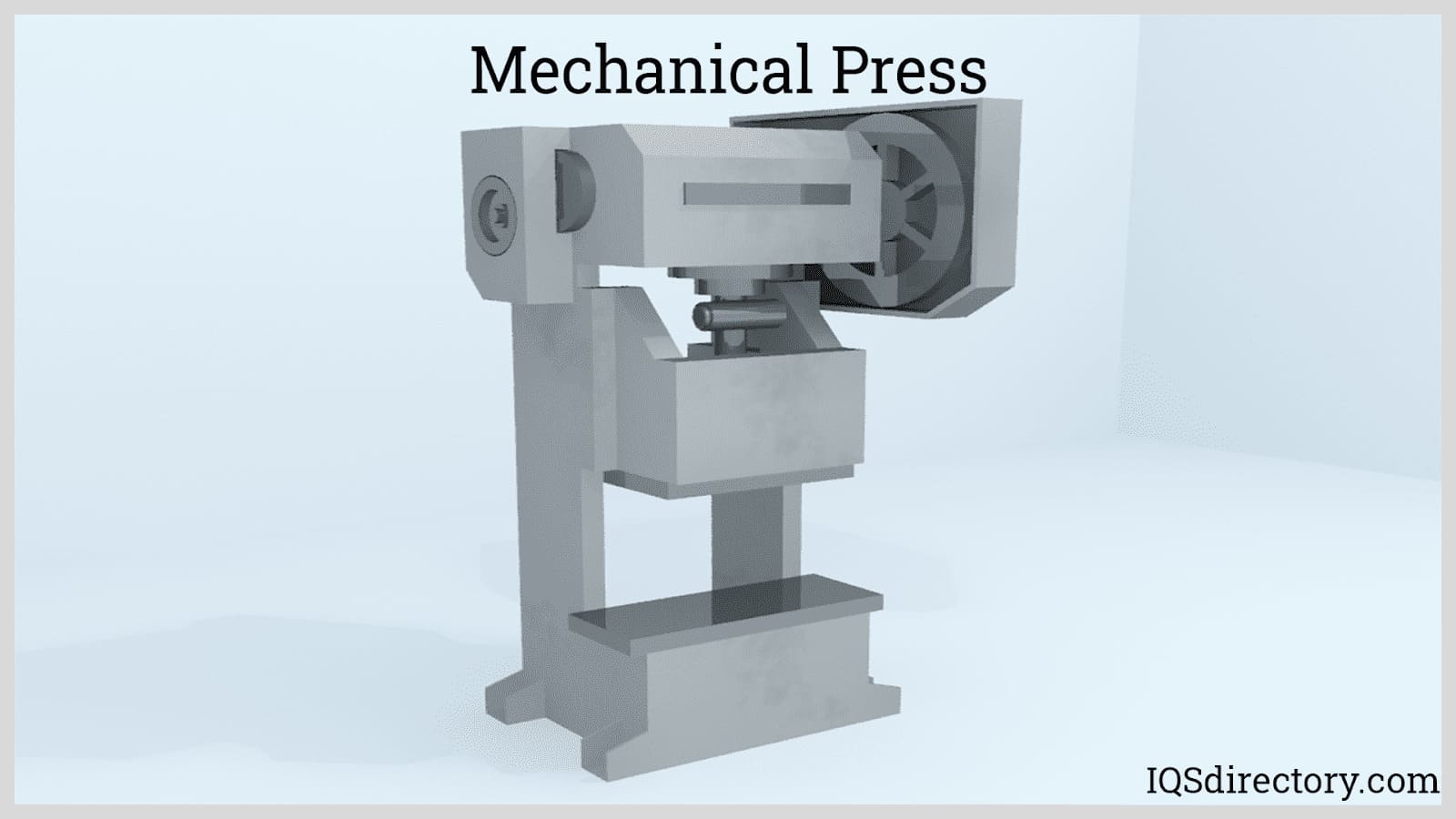

Mechanical Press

The ram of a mechanical press moves linearly while the motor rotates, gradually applying pressure to the die. An air clutch operates the machine pushed down by a motor. Similar to how clay is pressed into the form of a palm, the press's crankshaft exerts constant, consistent pressure on the ram throughout the stroke.

The greatest pressure is applied at the end of its stroke, when the object is pressed into its final shape. During the mechanical forging process, the dies are subjected to a large amount of stress and little impact force. To avoid breakage and damage, harder dies are employed. For mechanical forging press, tooling and die fabrication are high costs. The time-consuming and laborious procedure of changing dies is added to the expense of dies.

Screw Press

Motors that are both mechanical and hydraulic drive a screw press. A screw mechanism actuates the ram movement of a screw press. This type of press produces the ram's downward force by converting the flywheel's revolving energy and screw. The screw constantly rotates as the ram pushes down for one stroke to generate more energy and, thus, higher pressure. After one complete stroke, the screw and flywheel must turn counterclockwise to return to their initial positions. With knockout and liftout pins in the center of the die, one can swiftly remove the metal parts after being tightly squeezed into new shapes.

Upsetter Press

The process of horizontal upset forging involves an upsetter press. First, bars and tubes are bent into intricate shapes using this technique. Then, by sandwiching a bar between two dies and exerting pressure to the side, which bends the axis, hot upsetting forged is finished. Current presses can precisely bend a tube several times thanks to modern technology.

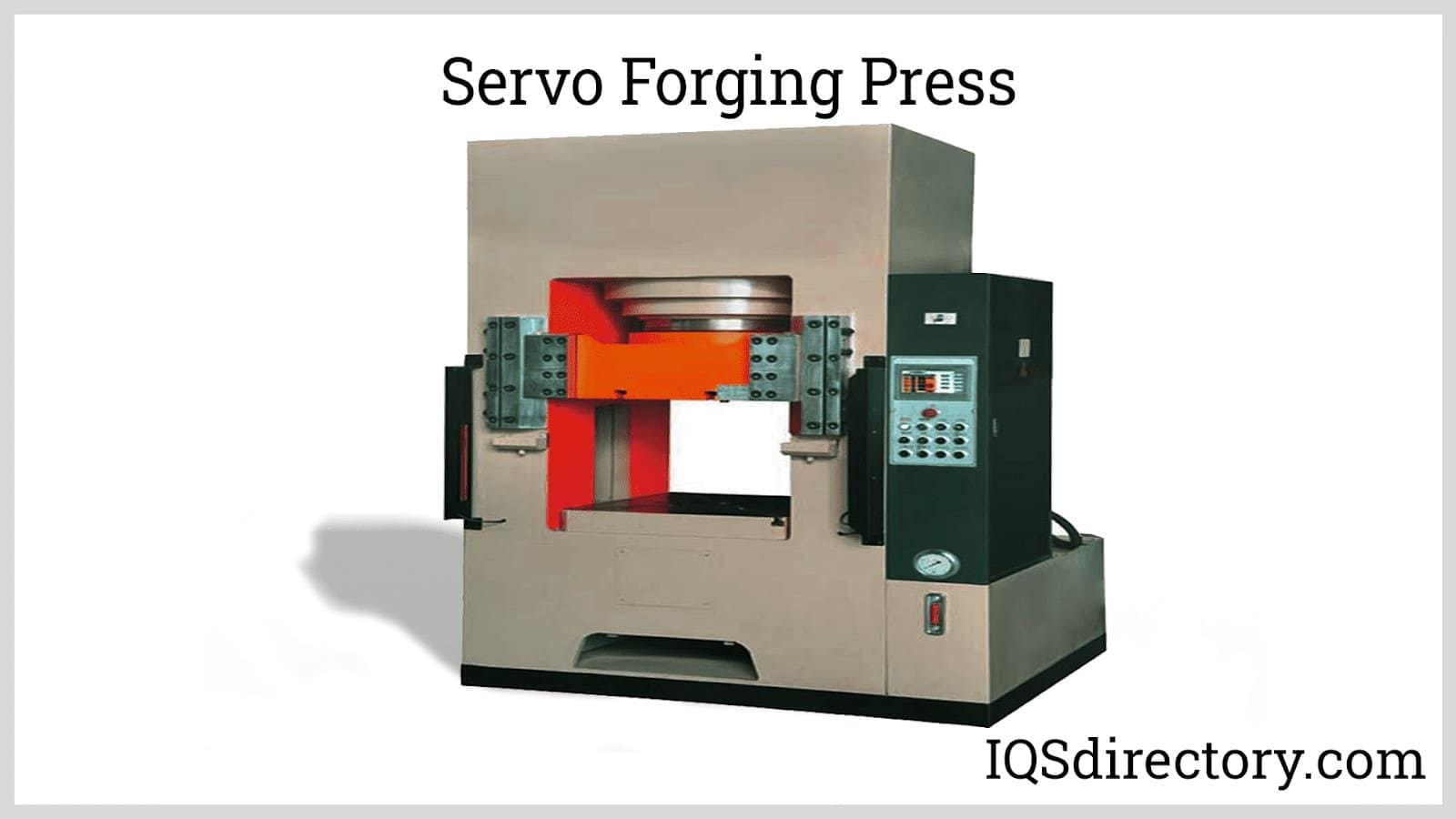

Servo Forging Press

A servo motor that presses down on the dies is directly connected to the press crankshaft via a belt, a pair of gears, and ball screws. In action, it resembles a hydraulic press, but it is more programmable and often rated for lesser tonnages.

Applications of Forging Presses

- Forging presses can produce automotive parts, especially when they need to be made in great volumes. In addition, forging presses can be used to manufacture crankshafts, connecting rods, and camshafts.

- Manufacturing large industrial valves employ forging presses because of the greater precision needed in the industry.

- Forging presses create parts for mining equipment such as transmission components, gears, levers, shafts, spindles, ball joints, wheel hubs, rollers, yokes, axle beams, bearing holders, and links. Most of the shaft-like pieces are produced using upsetter presses.

- Due to their adaptability and robustness, screw presses are frequently used for bigger manufacturing operations. Furthermore, with the current interest in space flight, the demand for specialized, high-crafter materials is anticipated to expand. Therefore, screw presses may become more significant in the years to come.

- Additionally, governments use mechanical presses for the coin-molding process.

Benefits of Forging Press

- A forging press completely deforms the work item and controls its rate of compression.

- The forging press can make an item in any size and shape.

- It needs less draft and generates less scrap.

- They create a product with outstanding mechanical qualities, such as increased tensile strength and superior fatigue resistance.

- Press forging often uses less draft than hammers.

- The forging press produces less scrap and can be more economical for high-volume jobs.

Choosing the Right Forging Press Manufacturer

To ensure the most productive outcome when purchasing a forging press from a forging press manufacturer, it is important to compare several companies using our directory of forging press manufacturers. Each forging press manufacturer has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each forging press business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple forging press companies with the same form.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services