Through the bonding process, laminating presses are able to provide these substrates with additional beneficial characteristics such as UV-protection, water-proofing and light-resistance. Read More…

The hydraulic press industry is competitive, but in a sea of competitors, we are among the best! We offer ISO 9000:2000 certification, and we work with customers to create the ideal designs for their unique circumstances.

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

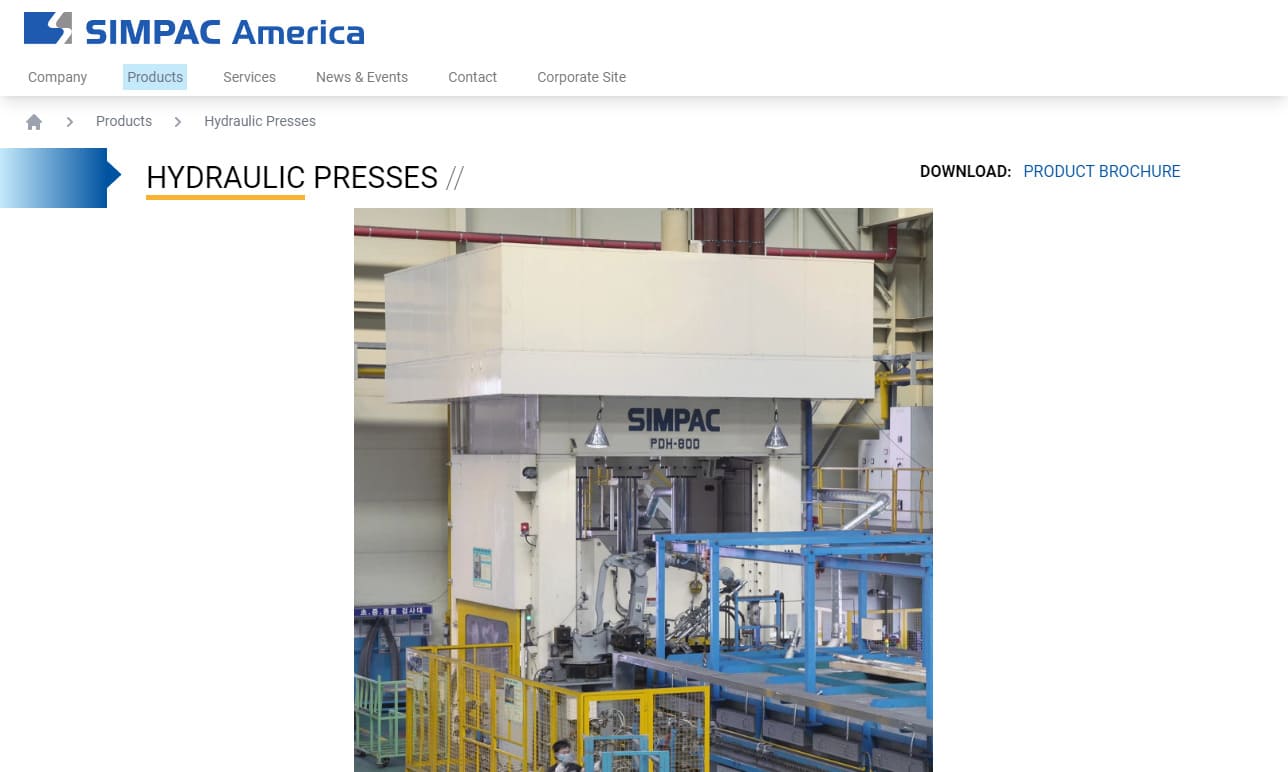

At SIMPAC America Co. Ltd., we are at the forefront of precision engineering and innovative solutions in the field of mechanical presses, servo presses, and hydraulic presses. With a commitment to excellence and a rich legacy spanning several decades, we have established ourselves as a trusted name in the manufacturing industry. SIMPAC America offers a comprehensive range of mechanical presses...

Air-Hydraulics is a manufacturer of air presses and a variety of hydraulic presses, including pneumatic air presses, power presses, hydraulic press stamping and assembly presses. We are ISO 9001:2000 certified and have been designing press machinery for metal forming and stamping since 1945.

More Laminating Press Manufacturers

Laminating presses have multiple openings, one for each plate, and precise controls for temperature and pressure. Multilayer laminating presses apply both pressure and heat to laminate and pre-preg to make multilayer boards.

Laminating presses are utilized in a wide range of applications and industries including: sports and recreation, in which laminated fabrics are often used for athletic apparel such as footwear; industrial manufacturing, for use in the lamination of structural components for industrial furniture such as workstations; construction, in order to laminate building materials such as kitchen or bathroom counter tops or flooring; research, for the lamination of various laboratory furniture for extra protection and sterilization; and electronics, to laminate electrical devices such as printed circuit boards (PCBs).

Also known as laminators or laminating machines, laminating presses are often thought of as their commercial version, small desktop machines used for ID cards, pictures, name tags and more. However, laminating presses can be very large pieces of industrial equipment as well.

Industrial-sized laminating presses feature stacked heating and cooling platens, laminating presses operate by heating one opening of the press while cooling the other; thus, fast lamination results are achieved.

The platens of the laminating press may be heated by steam, oil, or electrically. Once heated, the polymeric material, which could include plastics such as vinyl, polyester or polyurethane, is melted and adheres to the substrate. Then, when cooled, the material bonds to the surface of the substrate, resulting in a thin layer of protective polymeric material.

Typically, laminating presses are a type of hydraulic platen press, which are defined by the large, heavy, flat metal plates that they use in order to crush and condense materials.

In a laminating platen press, the bottom platen typically remains stationary, while the top one moves up and down.

The movement of the top platen is powered by hydraulics, which is defined as movement or operation through the use of pressure created by liquids, typically water.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services