Presses that can handle ton capacities are well suited for molding, cutting or shaping composites, laminates, plastics and rubbers. Depending on the application, it is possible to find machines capable of processing loads from two tons to even ten thousand tons. Read More…

The hydraulic press industry is competitive, but in a sea of competitors, we are among the best! We offer ISO 9000:2000 certification, and we work with customers to create the ideal designs for their unique circumstances.

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

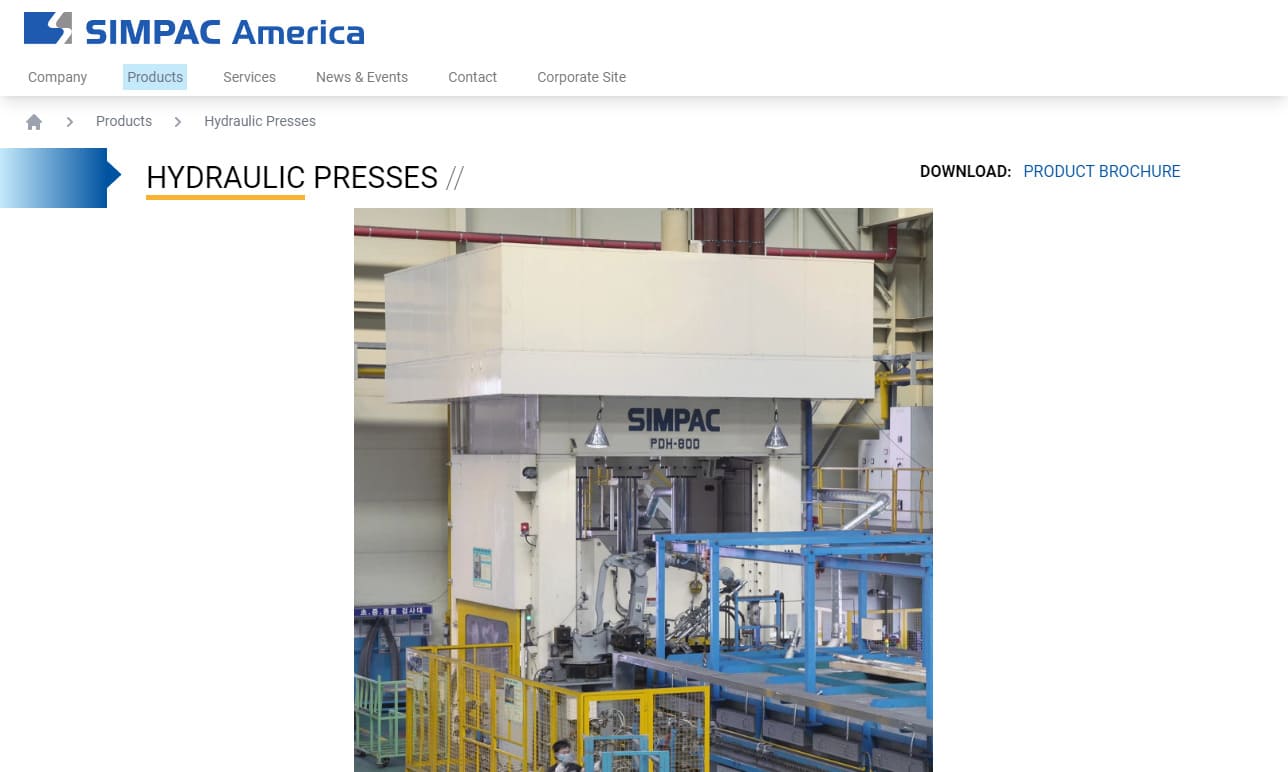

At SIMPAC America Co. Ltd., we are at the forefront of precision engineering and innovative solutions in the field of mechanical presses, servo presses, and hydraulic presses. With a commitment to excellence and a rich legacy spanning several decades, we have established ourselves as a trusted name in the manufacturing industry. SIMPAC America offers a comprehensive range of mechanical presses...

Air-Hydraulics is a manufacturer of air presses and a variety of hydraulic presses, including pneumatic air presses, power presses, hydraulic press stamping and assembly presses. We are ISO 9001:2000 certified and have been designing press machinery for metal forming and stamping since 1945.

More Ton Press Manufacturers

Forging presses, platen presses and stamping presses are types of hydraulic presses often designed with the ability to press by using almost any amount of force in the measurement of tons.

Presses such as these are preferred by industrial manufacturers because of their leading capability, performance, precision and reliability. Presses come with as little as two tons to ten thousand ton variants. Otherwise, most manufacturers can design models that are tailored to the needs of specific industrial applications.

Since operation speed and amount of force is determined by both what product is being made and with what material, a hydraulic press can differ as to how many tons it can handle. When it comes to hydraulic presses, there is literally no lack in options and many businesses within the plastic, rubber and stainless steel industries benefit from their operations.

If it weren't for hydraulic presses, there would be no chalk for the chalkboard and there would be no relief from Aspirin. It is the laboratory press that is used to produce solid cylinders or tablets by compressing powders with a particular amount of force, thus producing chalk and pills for headaches.

These are the products coming from presses capable of pressing with a force of but two thousand pounds. But by using a greater force of one thousand to even ten thousand tons, strong metals like stainless steel and similar alloys can be crushed or pressed to exact specifications.

A number of aircraft, automotive and other large metal parts are made through the process of exerting a certain amount of ton force.

Hydraulic presses are very practical when it comes to high compact construction and high tonnage force.

Cold forgings are designed to withstand a pressure of up to fifty thousand tons or more and fluid cell presses that are run by hydraulics can press one hundred and fifty thousand tons or more.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services