They are used to apply veneer or laminate to 2 or 3 dimensional products or bond two materials together. The vacuum system removes entrapped air instead of compressing it, ensuring that no air will reappear in the course of the product’s life. The lack of air combined with high pressure ensures an air-tight seal, easily bonding materials together. Read More…

The hydraulic press industry is competitive, but in a sea of competitors, we are among the best! We offer ISO 9000:2000 certification, and we work with customers to create the ideal designs for their unique circumstances.

When it comes to the hydraulic press industry, you want nothing but the very best! We have over 50 years of experience in the industry manufacturing quality products for our customers.

Our hydraulic press designs are one-of-a-kind. We work with our customers to determine the best hydraulic presses for their applications. Here at Savage Engineering & Sales, Inc. we take customer satisfaction very seriously.

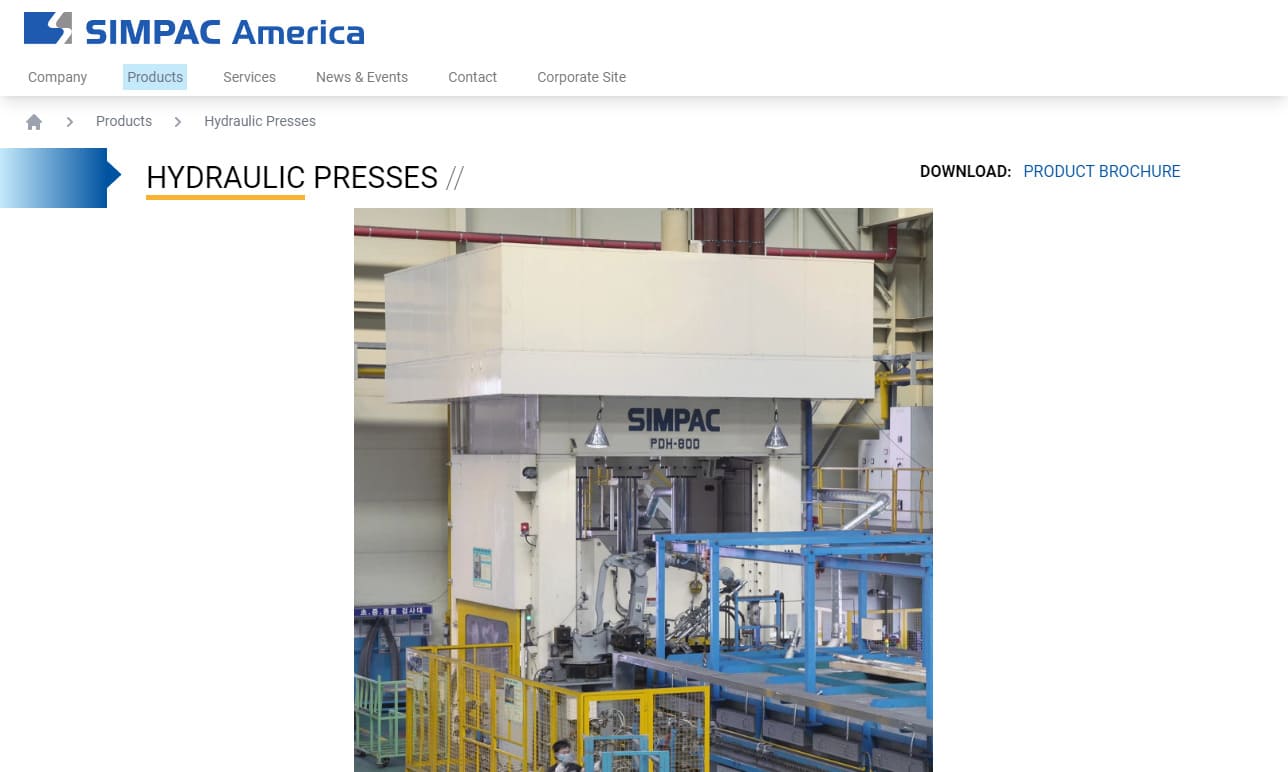

At SIMPAC America Co. Ltd., we are at the forefront of precision engineering and innovative solutions in the field of mechanical presses, servo presses, and hydraulic presses. With a commitment to excellence and a rich legacy spanning several decades, we have established ourselves as a trusted name in the manufacturing industry. SIMPAC America offers a comprehensive range of mechanical presses...

Air-Hydraulics is a manufacturer of air presses and a variety of hydraulic presses, including pneumatic air presses, power presses, hydraulic press stamping and assembly presses. We are ISO 9001:2000 certified and have been designing press machinery for metal forming and stamping since 1945.

More Vacuum Press Manufacturers

Vacuum presses are used in the furniture, construction, electronic and medical industries, and are generally found in workshops or industrial manufacturing facilities. They may be small and portable, but most of the time they are large, heavy equipment that stand alone or are part of an inline conveyor system.

Kitchen cabinets, doors and office furniture are often made of particle board, which are compressed wood ships and shavings that have a wood-like veneer that is applied to the exterior by a vacuum press as an alternative to real wood furniture.

Vacuum presses are also used to bond aluminum sheets and foam insulation, apply plastic laminate to countertops and tabletops, produce musical instrument parts, prosthetics, silicone heaters, solar panels, electronic materials, printed circuit boards, decorative laminates and honeycomb panels used in building construction.

Vacuum presses are made of a welded leak-free vacuum chamber that allows lamination at lower pressures, which, in some cases improves the quality of the products. Each lamination run takes approximately 5 to 7 minutes, but multiple products are able to be formed at once.

The vacuum press easily and completely removes trapped air and volatiles, and is able to achieve high psi ratings. The vacuum level is controlled by a vacuum gauge or vacuum transducer, and is often turn-key operated.

Small, portable vacuum presses are most likely found in small workshops, while large industrial vacuum presses are integrated into facility systems and include conveyors, loading and unloading systems, and heating and cooling systems. They are part of a continuous process and are often CNC operated meaning that they are fully automated, which nearly eliminates the need for human workers.

The advantage of CNC vacuum presses is that they are able to collect and store data, archive and keep track of information. The press is heated by thermal fluid running through the system.

All vacuum presses must be Occupational Safety and Health Administration (OSHA) compliant in addition to adhering to strict safety and quality regulations established by various other organizations.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services