French Oil Mill Machinery Company

French Oil Mill Machinery CompanyRequest A Quote

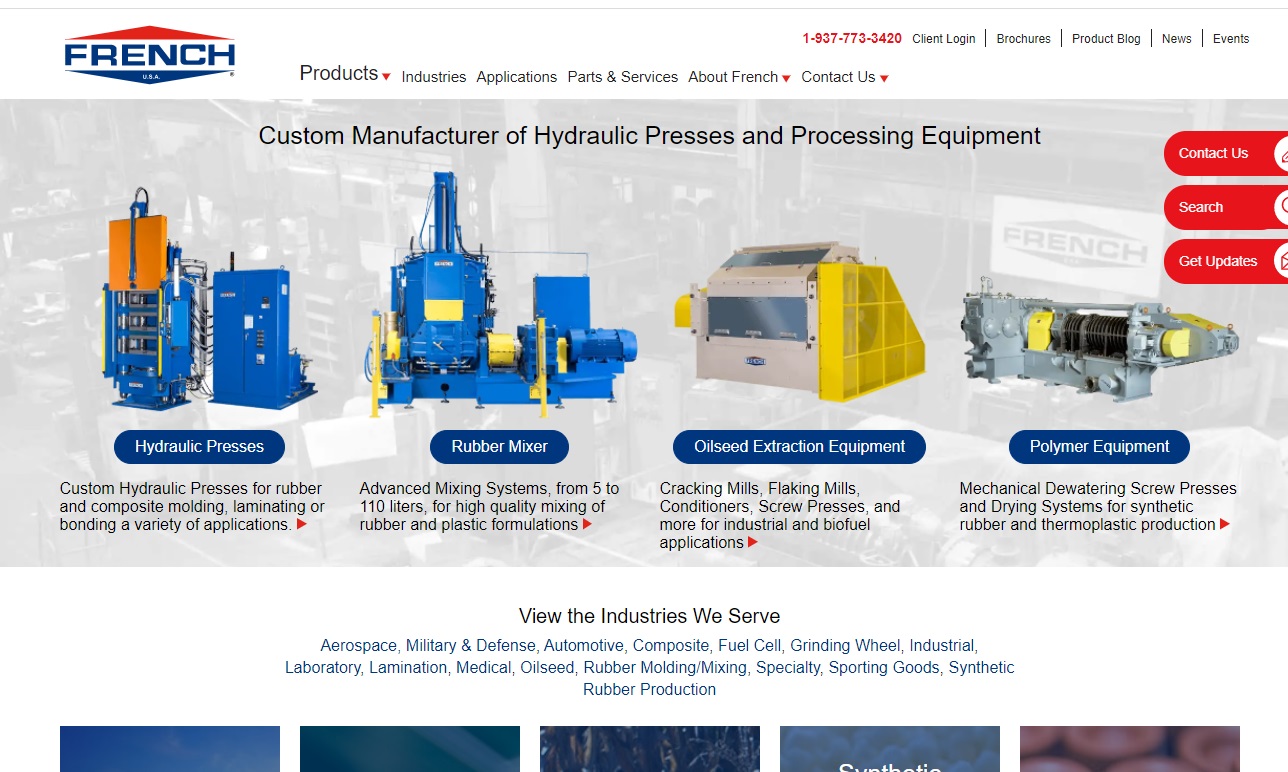

Piqua, OH | 937-773-3420French Oil Mill Machinery Company is a globally recognized leader in the manufacturing of hydraulic press solutions for various industries. French Oil Mill has built a strong reputation for delivering high-quality, durable, and technologically advanced hydraulic press systems. Our commitment to innovation, customer satisfaction, and industry expertise has positioned us as a trusted partner in the hydraulic press industry. French Oil Mill Machinery Company offers a diverse range of hydraulic press products designed to meet the unique needs and requirements of different industries. Our hydraulic presses are known for their robust construction, precision performance, and advanced features. Here are some key product offerings: We specialize in designing and manufacturing custom hydraulic presses tailored to the specific requirements of our customers. Our team of skilled engineers works closely with clients to understand their unique applications and develop customized solutions. From specialized tooling to advanced control systems, we have the capabilities to deliver fully customized hydraulic press solutions. Our vacuum hydraulic presses are designed for applications that require precise control over pressure and temperature. These presses are ideal for processes such as composite molding, rubber curing, and laminating. The vacuum feature ensures optimal part consolidation, reduced voids, and enhanced material properties. French Oil Mill offers automated hydraulic press systems that integrate advanced automation technologies for increased productivity and efficiency. These systems can be customized with features such as robotic part handling, material feeding, and real-time monitoring, allowing for seamless integration into production lines. They design custom presses for injection molding, transfer molding, and reaction injection molding processes. Other equipment they offer includes rubber mixers, fiber presses, oilseed extraction equipment, screw presses, and more. Our multi-opening hydraulic presses are designed to maximize productivity by allowing multiple parts to be formed or processed simultaneously. These presses are ideal for high-volume production and can significantly reduce cycle times, resulting in improved efficiency and cost savings. French Oil Mill Machinery Company is committed to providing comprehensive services that complement our hydraulic press products. Our team of experienced engineers provides expert engineering support to assist clients in selecting the right hydraulic press solution for their specific needs. French Oil Mill ensures a smooth and efficient installation process for hydraulic press systems. Our team of experts oversees the installation and commissioning, ensuring proper setup and integration into the customer's production facility. We strive for minimal disruption and quick turnaround to get operations up and running. We provide comprehensive training programs to equip operators and maintenance personnel with the knowledge and skills necessary to operate and maintain hydraulic press systems effectively. Our training covers safety procedures, machine operation, maintenance best practices, troubleshooting, and more. Additionally, our technical support team is readily available to provide ongoing assistance and guidance. French Oil Mill Machinery Company is a globally recognized leader in hydraulic press manufacturing, offering a wide range of high-quality products and comprehensive service capabilities. With our commitment to innovation, customer satisfaction, and industry expertise, we are the trusted choice for businesses seeking reliable and technologically advanced hydraulic press systems for their production needs.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services